Custom Furniture

Made-to-Measure for your desire

What Ecosphere Concept Delivers

Ecosphere Concept builds custom-made furniture for kitchens, bathrooms, bedrooms,

living rooms, and dining areas. We design the layout, engineer the details, produce the

furniture under controlled standards, and install it with a clean handover. If you want

one partner who can plan, build, and deliver a complete made-to-measure interior, this

is the scope.

Concept Interior Design — combined with made-to-measure furniture production and installation. We build custom kitchens, bathroom vanities, wardrobes, living room built-ins, and dining storage with consistent design language across rooms. We operate as part of the Ecosphere network and we control the production workflow so that responsibility is clear and outcomes are stable.

If you want a full interior solution that is built to fit, built to last, and managed with clear steps, the right next step is to define scope and priorities, measure the site properly, and build the project from specification — not from assumptions.

What “Custom Furniture” Means (And Why It Matters)

Custom furniture is often used as a marketing word. Here it has a simple meaning:

Furniture designed and built for your exact space and your real requirements.

That includes:

• Exact dimensions that fit your walls, ceilings, and openings

• A layout that matches how you live and how you use the room

• Materials and finishes chosen for the environment (heat, humidity, cleaning)

• Hardware that holds alignment and works smoothly over time

• Installation that is leveled, aligned, and properly fixed to the building structure Custom furniture is not just “nice-looking cabinets.”

It is functional planning turned into buildable, installable pieces. The result should feel natural to use and stable after years of daily use.

The key difference vs off-shelf furniture

The key difference between custom and off-the-shelf furniture lies in personalization, quality, and fit. Off-the-shelf pieces are designed for mass appeal, produced in standard sizes, and often made with cost-efficient materials, which can limit durability and design flexibility. In contrast, custom furniture is crafted specifically for your space and preferences, allowing you to choose the exact dimensions, materials, finishes, and features that match your needs. This tailored approach ensures better use of space, longer-lasting construction, and a more distinctive look, while ready-made options typically prioritize convenience and speed over individuality and precision.

What you are actually buying

You are buying outcomes:

• More usable storage without wasting space

• A cleaner, calmer look with fewer visible compromises

• Better daily workflow, especially in kitchens and bathrooms

• Durability: doors that stay aligned and drawers that keep working

• A consistent style across multiple rooms

When custom furniture is the right choice

Custom furniture is the right choice when you need pieces that perfectly fit your space, style, and lifestyle rather than settling for standard, mass-produced options. It allows you to maximize unusual layouts, small rooms, or specific functional needs by tailoring dimensions, materials, and finishes to your exact requirements. Custom pieces also offer higher quality craftsmanship and durability, since they are often built with better materials and attention to detail. Beyond practicality, they give you the freedom to express your personality and create a cohesive design that matches your vision, making your home or workspace feel more unique, comfortable, and long-lasting.

Who are we ?

Ecosphere Concept, Concept-ID, and the Ecosphere Network

Ecosphere Concept is the interior design and made-to-measure furniture unit within the Ecosphere network, operating on a straightforward and disciplined model: plan the interior properly, specify it clearly, produce it with full control, and install it with accountability. The name “Concept-ID,” short for Concept Interior Design, reflects this approach from the very beginning—“Concept” means every project starts with a defined interior logic that considers function, layout, and a consistent visual language across all rooms, while “ID” emphasizes that our work goes beyond decoration into practical, buildable design supported by precise planning and technical detailing. In simple terms, Concept-ID describes a process where concept-led interior design is directly translated into real, manufacturable furniture and reliable on-site installation. Being part of the Ecosphere network is equally important in practice, because unlike many interior brands that act only as intermediaries—selling a project and then outsourcing production and installation to separate, disconnected teams—we operate with an integrated structure that minimizes handovers and closes gaps in responsibility. This results in better coordination, clearer accountability across design, production, and installation, dependable local execution, predictable logistics, and consistent documentation and handover standards. Our “own production” model supports this by giving us control over the entire workflow, from preparing technical drawings and specifications before manufacturing begins, to defining materials and hardware, performing quality checks during assembly and before delivery, applying careful packaging to reduce transport damage, and planning installations methodically rather than improvising on site. While we may source certain specialized components when appropriate—as any serious producer does—the responsibility for the final outcome always remains with us, ensuring that what is designed is exactly what gets built and installed.

What We Build: Made-to-Measure Furniture

If your scope is broad — kitchen, bathroom, bedroom, living room, dining room — the best results come from one consistent system. That means one set of proportions, lines, and finish logic that carries across rooms. You avoid a “mixed” look where each room feels like a different supplier.

Kitchens

Custom kitchens, fitted kitchens, cabinetry

A kitchen is a workflow space. A good kitchen is not defined by the number of cabinets. It is defined by movement, access, storage zoning, and clean integration of appliances.

Typical kitchen elements we produce:

• Base units, wall units, tall units

• Pantry systems and pull-out storage

• Appliance housings and integrated panels

• Islands, breakfast bars, and storage benches

• Worktop support, splashback coordination, and service access.

Kitchen decisions that impact daily life

• Drawer systems vs. door cabinets (frequency and payload)

• Hardware quality (hinges and drawer slides define the feel)

• Counter height and usable workspace

• Lighting integration (task lighting changes everything)

• Ventilation and appliance access (avoid heat and service problems)

Bathrooms

Vanity units, storage, and moisture-aware solutions

Bathrooms fail when moisture detailing is weak. Swelling boards and peeling edges are not “normal.” They are usually caused by wrong materials, unsealed edges, or poor installation.

Common bathroom pieces:

• Vanity units with drawers and organizers

• Mirror cabinets and recessed storage

• Laundry cabinets and tall utility storage

• Shelving, niches, and concealed access panels.

What we take seriously in bathrooms

• Moisture-resistant materials and sealed edges

• Hardware that tolerates humidity

• Correct clearances around pipes and fixtures

• Easy-to-clean finishes that still look premium

Bedrooms

Wardrobes, fitted closets, and storage systems

Bedrooms are storage economics. The goal is to increase usable volume without making the room feel heavy.

Typical bedroom scope:

• Fitted wardrobes (hinged or sliding)

• Walk-in closets and dressing rooms

• Bed wall systems and headboard solutions

• Side units, storage benches, and integrated lighting niches.

Wardrobe performance criteria

• Stable alignment (doors should not drift)

• Quiet and durable runners for sliding systems

• Practical interior zoning: long-hang, short-hang, shelves, drawers

• Lighting that is serviceable and not “sealed forever”

Living rooms

Living rooms need balance: display areas plus closed storage. Custom-built media walls also need technical planning so cables and device heat do not become future problems.

Typical living room elements:

• TV walls and media cabinets

• Storage benches and wall-to-wall units

• Floating shelves and display cabinets

• Cable management and concealed power access.

The non-negotiable detail

Ventilation and access for devices. A beautiful media wall that overheats equipment or hides cables without access is a failure in slow motion.

Dining rooms

Sideboards, storage, and clean integration

Dining rooms often benefit from a custom sideboard that matches the kitchen language. It keeps the space clean and adds practical storage for serving items and seasonal equipment.

Typical dining elements:

• Sideboards and storage walls

• Integrated display niches and lighting

• Material coordination with adjacent rooms

One design language across rooms

• The same door style or a controlled family of styles

• Matching tones and finishes across rooms

• Consistent handle logic (or consistent handle-free detailing)

• Similar reveal sizes and alignment lines

• Lighting that follows one plan instead of random fixtures.

Quality - Materials, hardware, installations

Quality in furniture and interiors is not something added at the end but a system where materials, hardware, finishes, and installation must work together, since the final result is only as strong as its weakest link. A piece may look premium yet still fail if edges are poorly sealed, hardware is weak, or installation is rushed. Materials are selected for real conditions like moisture, heat, cleaning, and structural load, focusing on stability and proper construction rather than simply thickness. Hardware defines the daily experience through smooth, reliable movement, while finishes must resist scratches, wear, and easy damage. In the end, true quality comes down to consistent durability and precise installation, because even well-made furniture will look poor if it’s fitted carelessly.

How we work - progress...

Step 1 — Brief: scope, priorities, and constraints

We clarify:

• Which rooms are included and what “done” means

• Functional priorities (storage, workflow, comfort)

• Style direction and material preferences

• Budget corridor (a realistic range)

• Timeline and any critical dates

If a provider avoids budget discussion early, the project will usually break later — through redesign loops, poor material choices, or rushed installation.

Step 2 — Site measurement and reality check

Made-to-measure requires measurement discipline. We check:

• Wall straightness and angles

• Floor level changes

• Ceiling heights and drops

• Utility points (water, drainage, power, ventilation)

• Access constraints for delivery and installation.

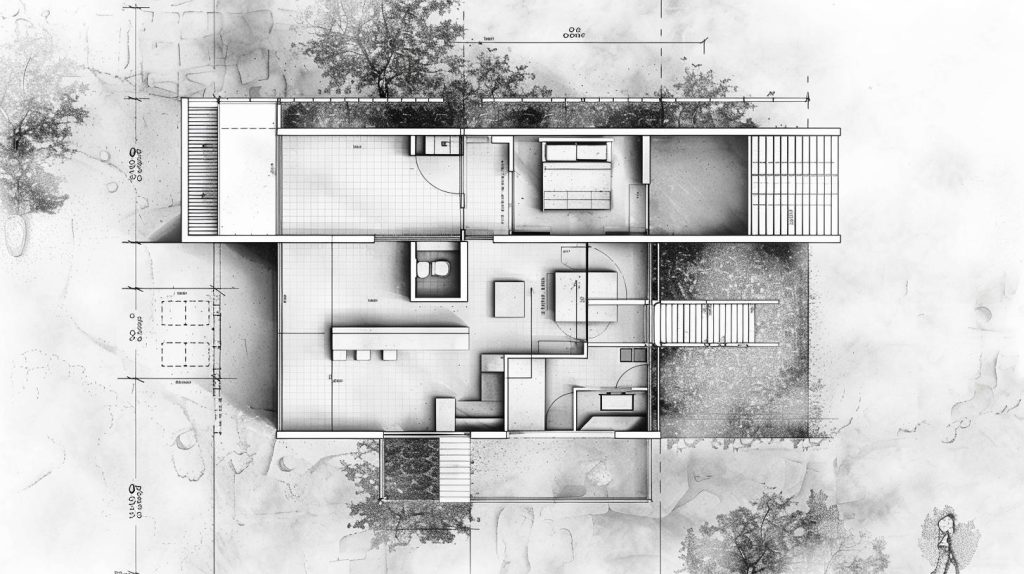

Step 3 — Concept-ID planning: function and visual system

This is where interior design becomes buildable:

• Layout logic: what goes where and why

• Consistent proportions and lines

• Finish coordination across rooms

• Lighting integration planning

• Serviceability planning (access, maintenance).

Step 4 — Technical specification and sign-off

Before production starts, we lock:

• Dimensions and construction details

• Materials and finishes

• Hardware specifications

• Edge treatments and visible detailing

• Installation plan and sequencing.

Step 5 — Production and quality control

Production includes:

• Controlled cutting and assembly

• Surface and edge checks

• Hardware fit and alignment checks

• Packaging to protect during transport.

Step 6 — Delivery, installation, and adjustment

Installation includes:

• Alignment and leveling

• Correct fixing to the wall type

• Door and drawer adjustment

• Clean finishing where required

• Final check against the agreed specification.

Step 7 — Handover and aftercare

You receive a clear handover status and care guidance. If you need service later, the path is defined. This is basic professionalism, but surprisingly rare.

How to Evaluate Offers

Pricing, Timelines, and Red Flags

What drives cost in custom furniture

• Total volume of cabinetry and complexity of the layout

• Finish category (basic to premium)

• Hardware quality level

• Complexity: angles, special mechanisms, curved work, difficult walls

• Installation environment and access

If an offer is dramatically cheaper than all others, it usually hides a downgrade in materials, hardware, or installation time. That downgrade becomes visible later, not on day one.

What drives timeline

• Scope size (one room vs. full home)

• Production load and material availability

• Engineering and specification time

• Site readiness (flooring, painting, utilities completed)

A serious plan includes milestones. A vague promise without milestones is not a plan.

Budget strategy

• Invest more in kitchens and bathrooms (high use, moisture, heat)

• Standardize internal wardrobe layouts where possible

• Use premium accent finishes selectively instead of everywhere

• Avoid unnecessary complexity that adds cost without value.

Professional quote includes:

• Clear scope per room (included and excluded items)

• Material and hardware categories, not vague labels

• A timeline with milestones (design, production, installation)

• Payment structure tied to milestones

• A basic change policy and acceptance criteria at handover.

Red flags

No clear material and hardware specification

• Vague pricing with unclear inclusions / exclusions

• Unrealistic timelines without milestones

• No change policy (changes always happen; the question is how they are handled)

• Poor references: only wide-angle photos, no detail shots

Reviews

Trustindex verifies that the original source of the review is Google. Nach mehreren Anlaufstellen in Sachen Auswanderung nach Montenegro hatten wir es zum Glück auch mit ekosphere in Ulcinj zu tun und sind echt zufrieden! Daniel und Ekrem sind super erreichbar, erklären’s normal (ohne Fachchinesisch) und kümmern sich wirklich, dass Dinge vorankommen. Keine Show, kein bla bla, keine Selbstinszenierung – einfach machen. Würde ich auf jeden Fall weiterempfehlen.Trustindex verifies that the original source of the review is Google. +++Endlich angekommen+++ Absolute Empfehlung! Wer nach Montenegro auswandert, merkt schnell, dass vieles anders läuft als gewohnt. Die Integrationshilfe hier war für mich der absolute Gamechanger! Besonders hilfreich war für mich die Unterstützung bei der Jobsuche: Hier werden nicht nur Stellenanzeigen weitergeleitet, sondern echte Kontakte geknüpft! ⭐⭐⭐⭐⭐ Was den Service aber wirklich einzigartig macht, ist die Rolle als verbindliche Anlaufstelle. Egal ob es um Behördengänge oder die kleinen Feinheiten der montenegrinischen Gepflogenheiten und Sitten geht – man bekommt immer eine fundierte Antwort. Man fühlt sich nicht wie ein Kunde, sondern wie ein Gast, dem ehrlich geholfen wird, Wurzeln zu schlagen. "Hvala lepo!"Trustindex verifies that the original source of the review is Google. Danke für die schnelle und einfache zusammen arbeit . Egal welches Problem, ekosphere doo hat es gelöst . Kann ekosphere doo weiter empfehlen. Lieben Dank an ekosphere dooTrustindex verifies that the original source of the review is Google. Firmengründung & Baukooperation – belastbare Struktur statt Show Als Bauleiter und Elektrofachmeister habe ich die Dienstleistung der ekosphere im Rahmen meiner Firmengründung in Montenegro in Anspruch genommen. Klartext: Das war kein Beratungszirkus, sondern saubere, umsetzungsorientierte Arbeit. Von Anfang an wurde strukturiert gearbeitet: rechtlicher Rahmen, Behördenwege, Timing, Zuständigkeiten – alles nachvollziehbar, ohne leere Versprechen. Genau das erwarte ich als jemand, der auf Baustellen Verantwortung trägt und Qualität liefern muss. Was mir besonders hängen geblieben ist: die Konsequenz in der Qualität am Bau. Keine Abkürzungen, keine Augenwischerei, klare Standards. In der Zusammenarbeit auf Projektebene zeigt sich, dass ekosphere Bau versteht – nicht theoretisch, sondern operativ. Schnittstellen zwischen Planung, Gewerken und Ausführung funktionieren, weil jemand mitdenkt. Ich bin bewusst hierhergezogen und arbeite heute partnerschaftlich mit ekosphere zusammen. Nach allen relevanten Auswahlkriterien – Fachlichkeit, Verlässlichkeit, Haltung – ist ekosphere für mich gesetzt. Wer Substanz sucht und nicht nur schöne Worte, ist hier richtig.Trustindex verifies that the original source of the review is Google. Kompetent, sympathisch, sehr zu empfehlen.Trustindex verifies that the original source of the review is Google. Absolut das kompetenteste Team in ganz Ulcinj und Umgebung was ich Kennenlernen durfte. Hier besteht Struktur und Expertise und nicht nur blabla. "Respekt"👍😉Trustindex verifies that the original source of the review is Google. Ich bin mit der ekosphere doo äußerst zufrieden! Sehr zuverlässig, professionell und immer termingerecht. Die Zusammenarbeit läuft jedes Mal reibungslos, und man merkt, dass hier Qualität und Kundenzufriedenheit an erster Stelle stehen. Ich kann die Firma uneingeschränkt weiterempfehlen und werde auch in Zukunft gerne wieder eure Dienste in Anspruch nehmen! Danke für eure Arbeit :)Trustindex verifies that the original source of the review is Google. Unsere Familie möchte der Firma Ekosphere doo und insbesondere Herrn Ekrem Rexhepagaj unseren aufrichtigen Dank aussprechen für die Hilfe in einer für uns sehr wichtigen Situation. Wir haben den Kauf eines Hauses in Montenegro in Erwägung gezogen, sind jedoch keine Fachleute im Bauwesen. Deshalb haben wir uns für eine Beratung an Ekosphere doo gewandt. Herr Rexhepagaj reagierte sofort und war so freundlich, persönlich zum Objekt zu kommen, um den Zustand des Gebäudes zu begutachten. Nach einer gründlichen Besichtigung erhielten wir eine ausführliche und professionelle Einschätzung: Das Haus befand sich in einem baufälligen Zustand, obwohl es oberflächlich durch eine kosmetische Renovierung gepflegt aussah. Dank der Kompetenz und Ehrlichkeit von Ekosphere doo konnten wir einen großen finanziellen Verlust vermeiden und die richtige Entscheidung treffen. Ein großes Dankeschön für die schnelle Reaktion, die Hilfsbereitschaft und den hohen Grad an Professionalität! Wir empfehlen Ekosphere doo jedem, der in Montenegro eine zuverlässige, ehrliche und kompetente Firma sucht. — Familie JerkeTrustindex verifies that the original source of the review is Google. I was impressed of what Ekrem built up in Ulcinj with Ekosphere. He showed me around and gave me valuable insights of opportunities in Montenegro. When I had personal issues during my stay he was there to help und support! A big thank you to him and also to his professional team.Trustindex verifies that the original source of the review is Google. Apartament w Ulcinj pod tym adresem super lokalizacja poza centrum miasta można odpocząć

We’re here for you

Feel free to contact us

Get in touch with Ekosphere Concept to bring your interior vision to life. Whether you’re planning a new home, apartment, or renovation project, our team is here to provide personalized design and furniture solutions. Visit us in Ulcinj, Montenegro, or reach out via ekosphere.me to start creating your perfect space today.

Kontact & Biro in Ulcinj

PIB: 0317 1868

REG: 5081 9609

PDV: 82 / 31-02022-6

Working hours: Mon–Fri 10:00–17:00

Appointments outside opening hours by arrangement

Weekend appointments possible by arrangement

- Bulevar Teuta, Ulcinj 85360

- Tel: +382 69 344 043

- Whatsapp: +382 30 681 227

- Email: office@ekosphere.me